ASTM D638

* This test method can be used for testing materials of any thickness up to 14mm.

Test Specimens

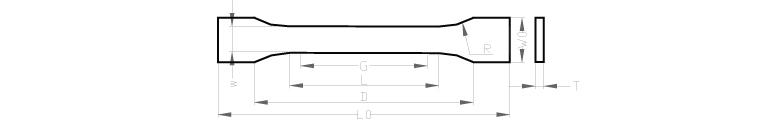

< TYPE Ⅰ,Ⅱ,Ⅲ,Ⅴ >

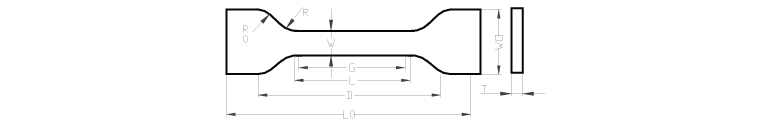

< TYPE Ⅳ >

* Specimen Dimension or Thickness. T[mm]

| Dimension | 7 or under | Over 7 to 14 | 14 or under | Tolerance | ||

|---|---|---|---|---|---|---|

| TypeⅠ | TypeⅡ | TypeⅢ | TypeⅣ | TypeⅤ | ||

| W-Width of narrow section | 13 | 6 | 19 | 6 | 3.18 | ±0.5 |

| L-Length of narrow section | 57 | 57 | 57 | 33 | 9.53 | ±0.5 |

| W0-Width over-all, min | 19 | 19 | 29 | 19 | ... | +6.4 |

| W0-Width over-all, min | ... | ... | ... | ... | 9.53 | +3.18 |

| L0-Length over-all, min | 165 | 183 | 246 | 115 | 63.5 | no max |

| G-Gage length | 50 | 50 | 50 | ... | 7.62 | ±0.25 |

| G-Gage length | ... | ... | ... | 25 | ... | ±0.13 |

| D-Distance between grips | 115 | 135 | 115 | 64 | 25.4 | ±5 |

| R-radius of fillet | 76 | 76 | 76 | 14 | 12.7 | ±1 |

| R0-Outer of radius(TypeⅣ) | ... | ... | ... | 25 | ... | ±1 |

* Designations for Speed of Testing : Select the lowest speed that produces rupture in 1/2 to 5 min for the specimen geometry being used

| Classification | Specimen Type | Speed of Testing mm/min | Nominal strain Rate at Start of Test mm/mm.min |

|---|---|---|---|

| Rigid and Semirigid | Ⅰ,Ⅱ,Ⅲ rods and tubes | 5±25% | 0.1 |

| 50±10% | 1 | ||

| 500±10% | 10 | ||

| Ⅳ | 5±25% | 0.15 | |

| 50±10% | 1.5 | ||

| 500±10% | 15 | ||

| Ⅴ | 1±25% | 0.1 | |

| 10±25% | 1 | ||

| 100±10% | 10 | ||

| Nonrigid | Ⅲ | 50±10% | 1 |

| 500±10% | 10 | ||

| Ⅳ | 50±10% | 1.5 | |

| 500±10% | 15 |

Calculation

* Tensile Strength

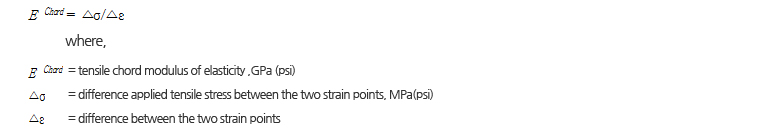

* Tensile Chord Modulus of Elasticity